Eco-Initiatives

At Foothill, it's not just our cucumbers that are "green". We want to be good stewards of the ecosystem around us, and are always open to investigating opportunities that are both viable from a business standpoint, and friendly to our environment. The fact that we operate indoors does not at all mean that we have no impact on the world around us.

Cogeneration

For many years our second generation owner, Ron Voorberg, had been intrigued by the idea of generating his own power, and using the heat byproduct to supplement the greenhouse heating needs. When the opportunity presented itself to come close to accomplishing this exact goal, the team at Foothill was prepared, and set in motion the necessary efforts to make this dream a reality.

In August of 2017 Foothill commissioned a new CHP plant on our farm. CHP stands for Combined Heat and Power, and is used as a term to describe a system that is designed to run on fuel to generate power, while capturing byproduct heat and using that heat for useful purposes. This is commonly referred to as "Cogeneration", which is also shortened to simply, "Cogen". In our plant, a Natural Gas fired engine coupled with a generator produces power for the Ontario electrical grid while simultaneously delivering hot water to the greenhouse heating system. When Ontario's energy grid is under heavy load, our plant is commissioned to run to meet peak demands. By capturing the heat and putting it to good use growing food, we can generate electricity in a more sustainable manner.

Water Recycling

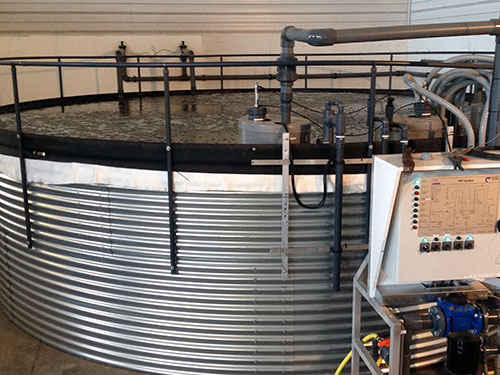

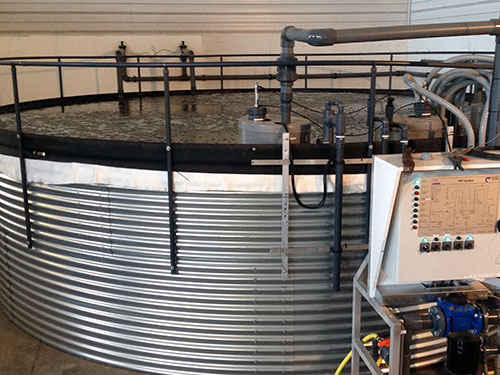

Freshwater is a natural resource growing in value around the world today, and it is also the most necessary ingredient to our success. Not only is our end product made up of over 90% water, but in the sweltering heat of the Canadian summers, we may apply irrigation volumes in excess of 100,000 Litres of nutrient-rich water to our cucumber plants per day. We have implemented processes and procedures over the past several decades that have enabled us to recycle nearly 100% of the water that the plants don't absorb.

Our hydroponic substrate that the plants are grown in is mounted on raised troughs that return the water to holding tanks where it can be sterilized of harmful pathogens, and reused. The big benefit is that this process maintains the nutrient content added upon initial introduction to the system. This means we can save on the input of a precious natural resource, as well as the amount of fertilizer input we need to supply the plants with the necessary nutrient value to thrive.

Solar Energy

As the world population grows, we all find it increasingly difficult to afford the cost of energy. It has also become apparent that our cultural and economic practices in North America have made our impact on the environment quite drastic. Techonological efforts are now being focussed on making renewable energy options more efficient and affordable for both commercial and residential uses and implementations.

Foothill Greenhouses Ltd. is proud to be participating in the Ontario government's microFIT Program in the Solar PhotoVoltaic (PV) division. Our two installations on the roofs of two separate material storage buildings fall each into the 10kW category, and have supplied in excess of 60,000 kWh to the Ontario electrical grid since the project's launch in the early spring of 2012.

Wood-waste and CO2 Recycling

Our woodburning systems use ground up materials from wood-construction waste, putting this extra material to good use. Our systems have changed greatly since we first began using this method in the 1980's, and the combustion process is quite clean and efficient. Combustion chamber temperatures can exceed 1000 degrees Celsius, enabling more complete combustion of the wood fuel. In fact, it can be so clean that the 'smoke' seen pumping out of our chimneys is actually mostly steam! In both our woodburning and natural gas burning boilers, Carbon Dioxide (CO2) is a natural by-product of combustion.

We have implemented special systems that siphon off the CO2 gas from the burn process, and transport it into the greenhouses in specific quantities, where the plants can consume it and expel Oxygen. This Oxygen ends up being released to the atmosphere outside through venting and air exchange, helping to further diminish our ecological footprint.